What Is the Mohs Scale? — Reclaim, Recycle, and Sell your Precious

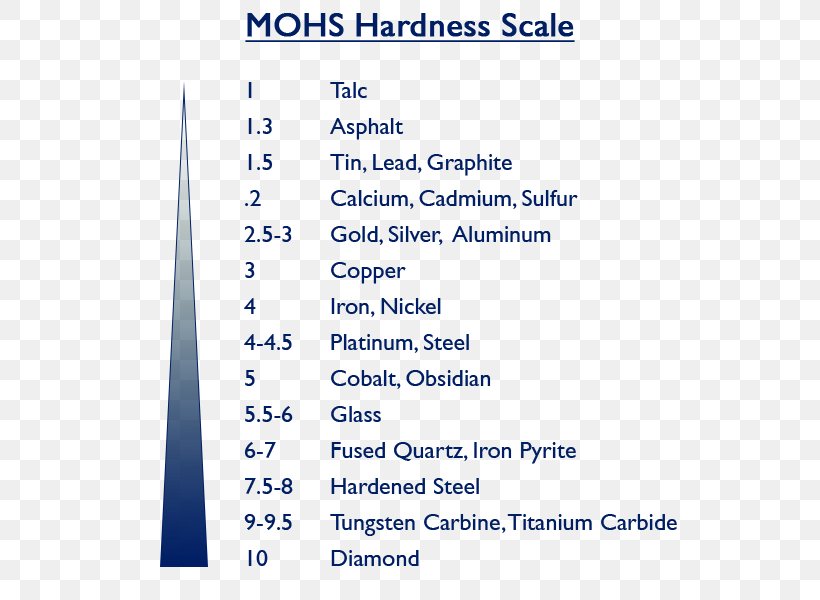

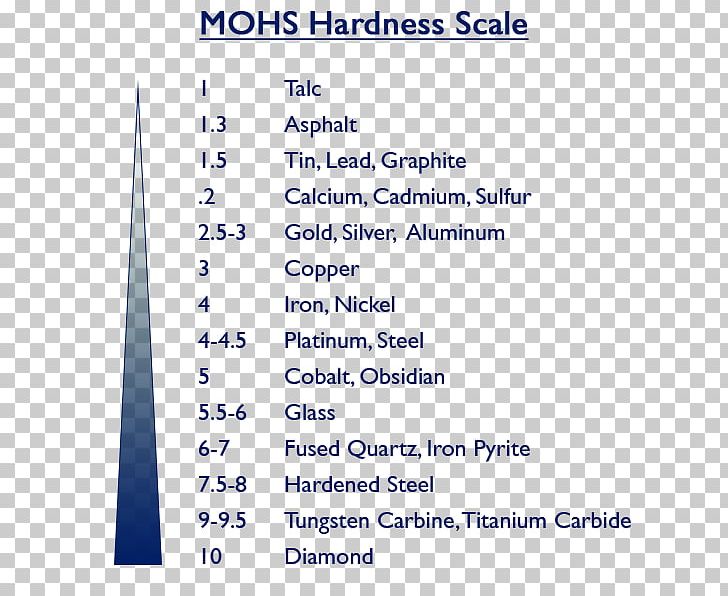

mohs hardness scale metals

For instance, metals like gold (Mohs hardness 2.5-3) and copper (Mohs hardness 3) are softer, while steel and iron (Mohs hardness 4-4.5) have intermediate hardness, and tungsten carbide (Mohs hardness ≥9) is one of the hardest materials. These metals can be used to scratch rocks to determine their hardness approximately and aid in identifying.

Mohs scale of mineral hardness Steel Steel Choices

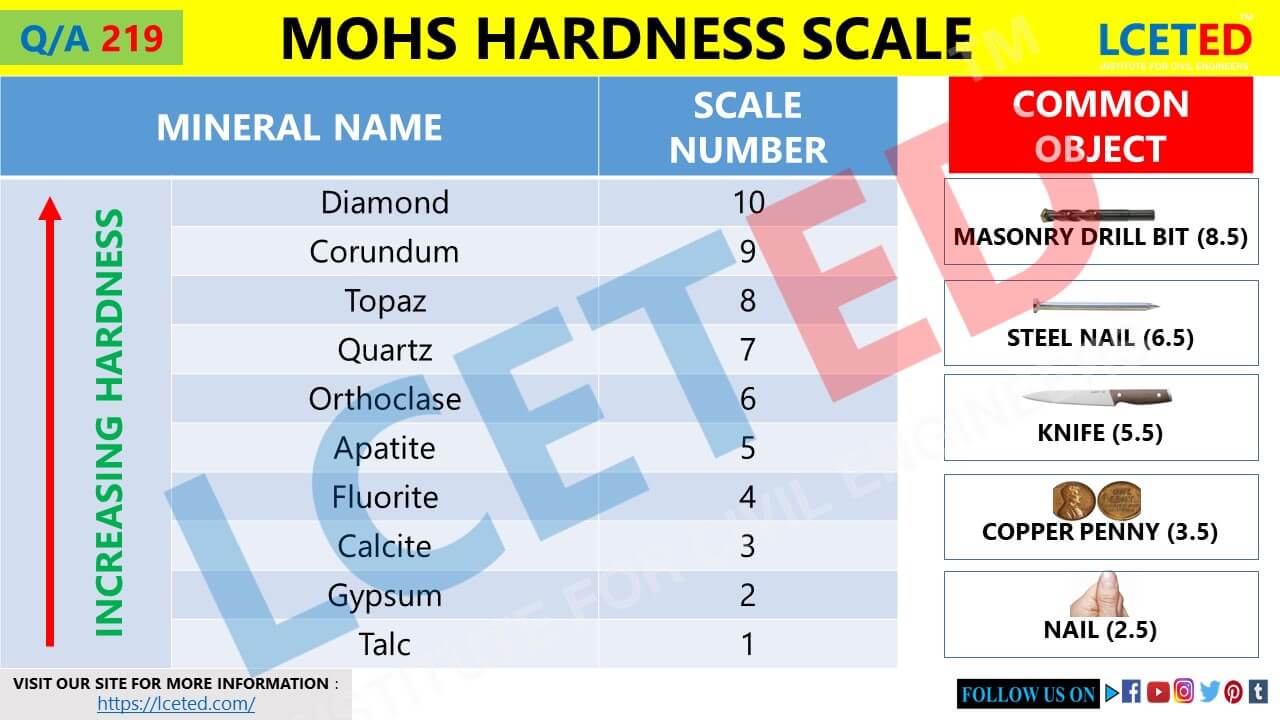

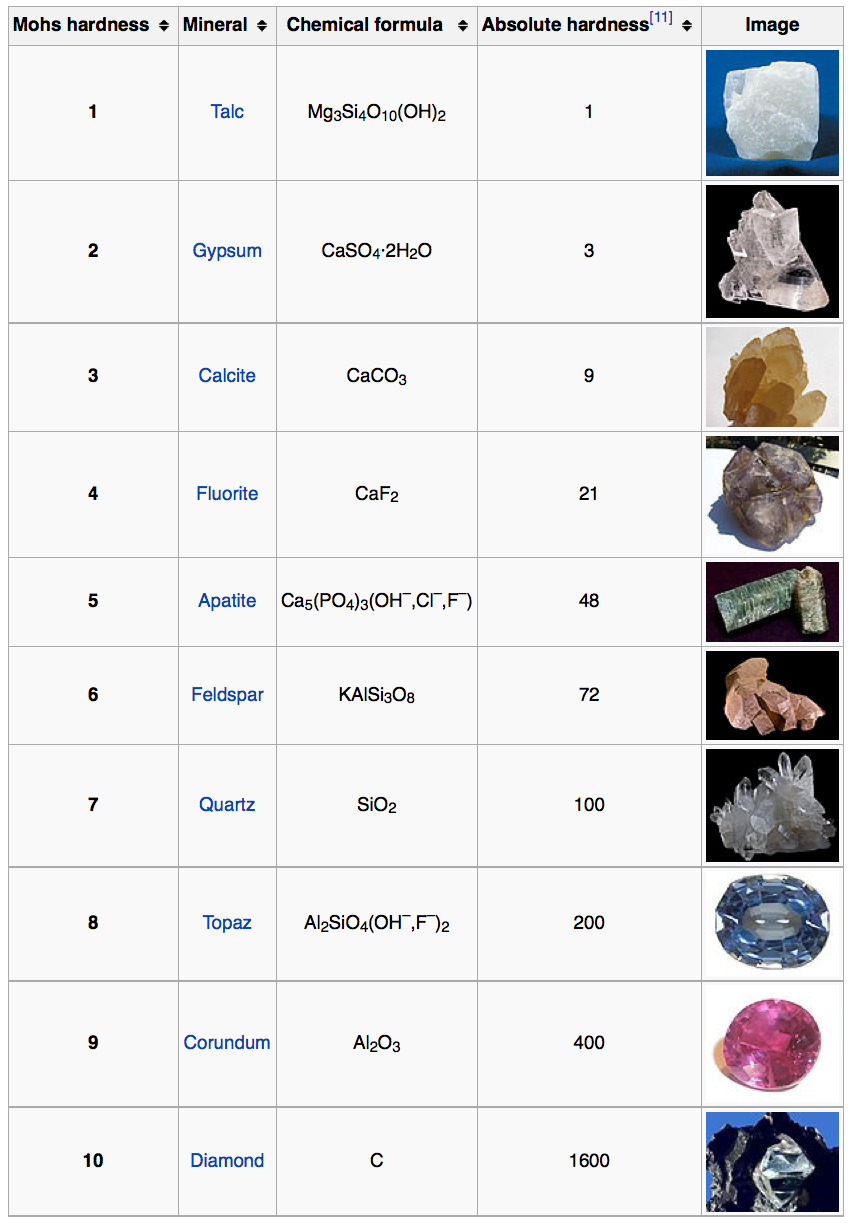

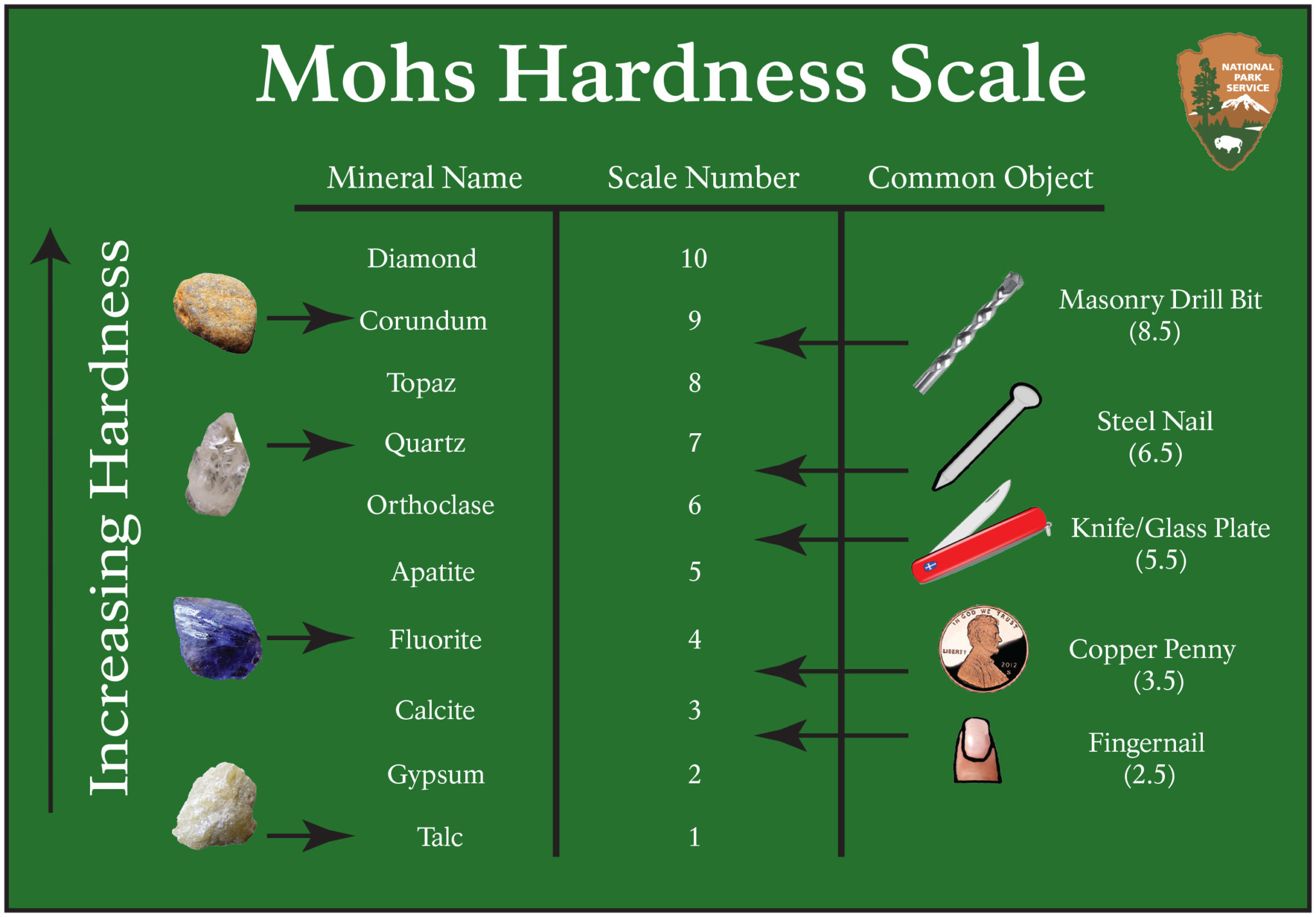

The Mohs hardness scale is based on ten minerals of different hardness, divided into ten levels from low to high: 1. Talc; 2. Gypsum; 3. Calcite; 4. Fluorite; 5. Apatite; 6. Orthoclase; 7. Quartz; 8. Topaz; 9. Corundum; 10. Diamond. In use, standard minerals are scratched against minerals of unknown hardness.

Mohs Hardness Scale Charts Printable

The Mohs scale is a system used to rank materials on their hardness, which is graded using numbers from 1 to 10. It can be used to compare gemstones, metals and other materials, and evaluate their relative durability. Where a metal stands on the Mohs scale indicates which other metals can scratch it.

Mohs Hardness Scale Geology Page

The Mohs hardness scale is a qualitative test that measures the hardness of a mineral by its ability to visibly scratch softer minerals. The scale isn't perfect, but it's a great tool for quick identification of rocks in the field.. topaz, cubic zirconia, spinel, hardened steel: 8.5: chrysoberyl, silicon nitride, tantalum carbide.

MOHS SCALED OF HARDNESS MOUNTED Eduscience

Hardness Hardness is the resistance of a material to the penetration of another, harder body. Hard-ness is also a measure of the wear resistance of steel. The hardness property is required 3.1 Properties of Steel. 66 3 Alloying Elements and Steel Properties for those components that are exposed to large forces and high wear, such as gears, roll-

Mohs Scale Of Mineral Hardness Hardness Comparison Hardened Steel, PNG

The Mohs hardness scale. Image credit: Philip Brayne for IFLScience Since then, other substances have been added using decimals. This guide, for example, slots in such relevant items as nails,.

What Is Mohs Scale Of Hardness? And How To Use It lceted LCETED

Mohs hardness, rough measure of the resistance of a smooth surface to scratching or abrasion, expressed in terms of a scale devised (1812) by the German mineralogist Friedrich Mohs. The Mohs hardness of a mineral is determined by observing whether its surface is scratched by a substance of known or defined hardness.

Mohs Scale Of Mineral Hardness Hardness Comparison Hardened Steel PNG

The Common Objects for hardness comparisons are listed a column to the left as: Masonry Drill Bit, 8.5; Steel Nail, 6.5; Knife/Glass Plate, 5.5; Copper Penny, 3.5; and Fingernail, 2.5.. The Mohs Hardness Scale is used as a convenient way to help identify minerals. A mineral's hardness is a measure of its relative resistance to scratching.

What Is the Mohs Scale? — Reclaim, Recycle, and Sell your Precious

ADVERTISEMENT What is Mohs Hardness Scale? The Mohs Hardness Scale is a set of ten reference minerals (numbered 1 through 10) that are used to determine the relative hardness of minerals and other objects. In this test the hardness of a mineral is defined as its "resistance to being scratched".

Infographic Mohs Hardness Scale of Metals 20180425 Industrial

The Mohs scale of mineral hardness ( / moʊz /) is a qualitative ordinal scale, from 1 to 10, characterizing scratch resistance of minerals through the ability of harder material to scratch softer material.

.jpg)

The Mohs Hardness Scale Geology In

By Alan Bernau Jr The Mohs Hardness Scale ranks metals and minerals by harness. This chart shows how steel, silver, aluminum, titanium, tin, brass, and other minerals compare.

Mohs Hardness Scale

The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is removed, leaving an indentation with a diameter of d.

The Mohs Scale of Hardness Explained YouTube

Because of low Mohs hardness, ZnS pigments cause virtually no wear on moulds and do not impair the mechanical strength of fibre-reinforced plastics (in contrast to abrasive pigments such as TiO2 ). Their main applications are in thermosetting compounds, glass fibre-reinforced thermosets and thermoplastics, and polyolefins. Table 7.3.

Mohs hardness scale Stock Image C010/9147 Science Photo Library

April 25, 2018. This metal hardness chart organizes different types of metal using the Mohs hardness scale, a metric used by scientists to determine the scratch resistance of different minerals. With diamond at the top of the scale at a score of 10, elements and alloys can fall along the metal hardness scale from 10 (the most scratch-resistant.

Moh's Hardness Scale International Granite And Stone

The Mohs hardness scale is a qualitative scale used to measure the scratch resistance of various minerals or materials. It was developed by Friedrich Mohs, a German mineralogist, in 1812. The scale ranges from 1 to 10, with 1 being the softest and 10 being the hardest. Each mineral on the Mohs scale can scratch all minerals with a lower number.

Infographic Mohs Hardness Scale of Metals 20180425 Industrial

The Mohs hardness test is one of the earliest attempts at defining and comparing the hardness of mineral materials. The Mohs scale consists of values from 1 to 10, which correlate with the ability of the test material to withstand scratching by progressively harder minerals.. (typically used for steel). The result of the testing process is a.